Application of Brinell Hardness Tester and Its Advantages and Disadvantages

Brinell hardness tester application:

As the Brinell hardness test use large pressure, large pressure head and large indentation diameter, it is suitable for metal hardness testing of the large grain.

Such as cast iron, nonferrous metals and their alloys, all kinds of quenched and tempered steel, annealed steel and most of the steel supplied by factory and so on.

The hardness test is very accurate, especially for the softer metals, such as pure aluminum, copper, lead, tin, zinc and its alloys.

Brinell hardness tester indication allowed error

Brinell hardness tester is the most commonly used hardness tester.

Advantages: Brinell hardness method has high precision, repeatability and good representation.

Insufficient: The operation time is long. The different soft and hard material samples need to be selected, the pressure head and detection force need to be replaced. Indentation measurement also takes some time.

1. Brinell hardness tester indication error

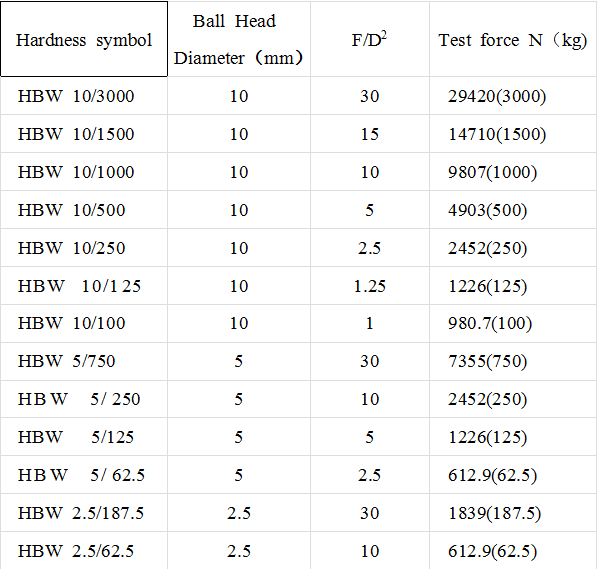

2. Correspondence of Brinell hardness test scale, indenter and test force

3. Correspondence of Brinell hardness test material, hardness and test force